close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

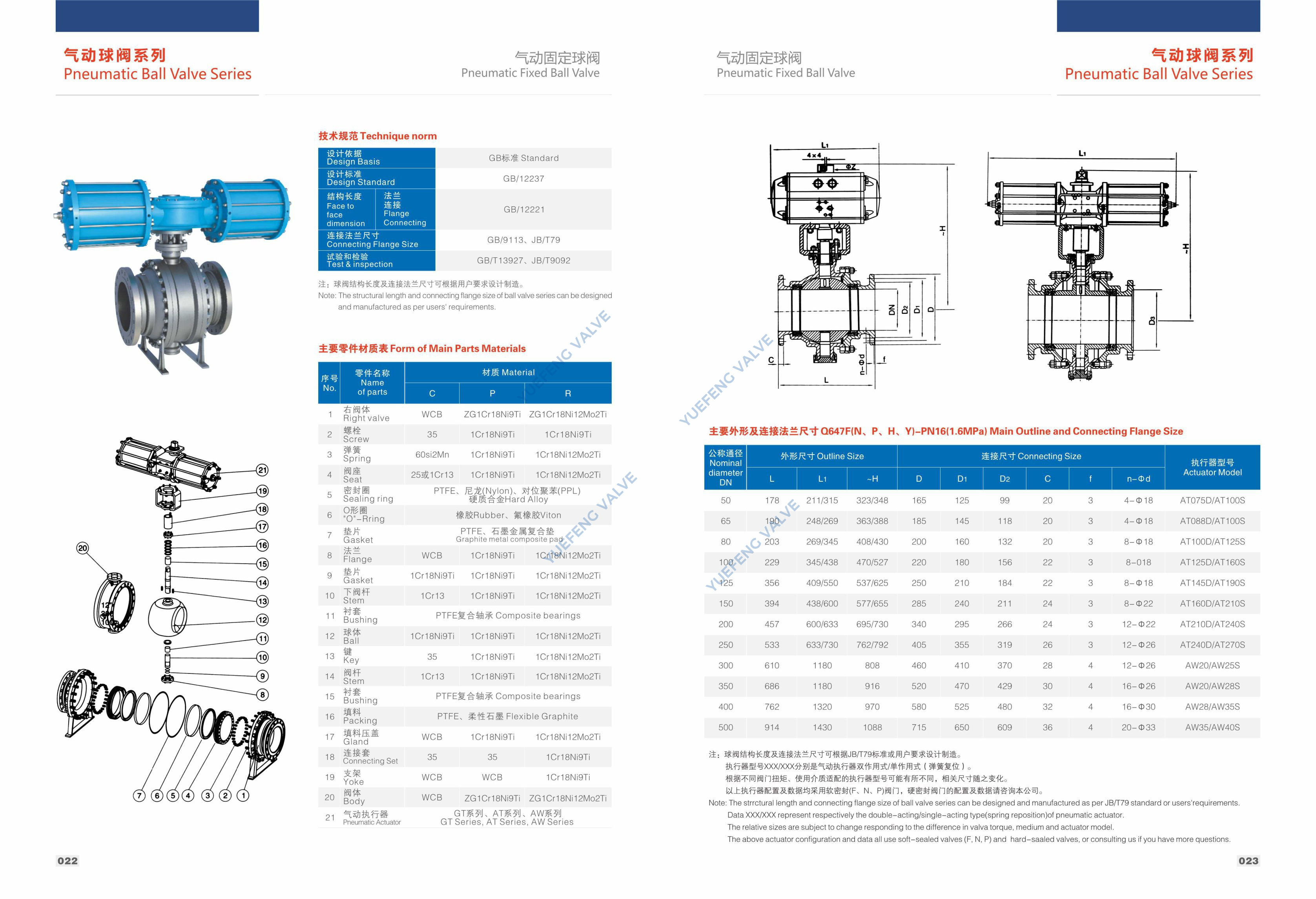

Compliant with rigorous standards including GB/12237 (design), GB/12221 (structural length), and GB/9113/JB/T79 (flange connection), this valve ensures compatibility and reliability in global industrial systems. It features a Flange Connection design for secure installation, covering a wide range of Nominal Diameter (DN) from DN50 to DN500 and Pressure Rating (PN) of PN16 (1.6MPa), PN25 (2.5MPa), and PN40 (4.0MPa) to meet diverse pressure requirements. Equipped with high-efficiency Pneumatic Actuators (AT, AW, and GT series), the valve supports both double-acting and single-acting (spring return) operation, delivering fast response and stable torque output. Available in Soft-sealed Valves (F, N, P) and Hard-sealed Valves configurations, it adapts to varying media characteristics, from non-corrosive fluids to high-temperature, high-pressure harsh conditions.

Built on GB/12237 and GB/12221 standards, the valve’s structural length and flange dimensions are optimized for durability and interchangeability. The fixed ball design minimizes fluid turbulence, reducing wear on internal components and ensuring long-term operational stability. Flange connections adhere to GB/9113 and JB/T79 specifications, guaranteeing leak-proof assembly and resistance to high pressure.

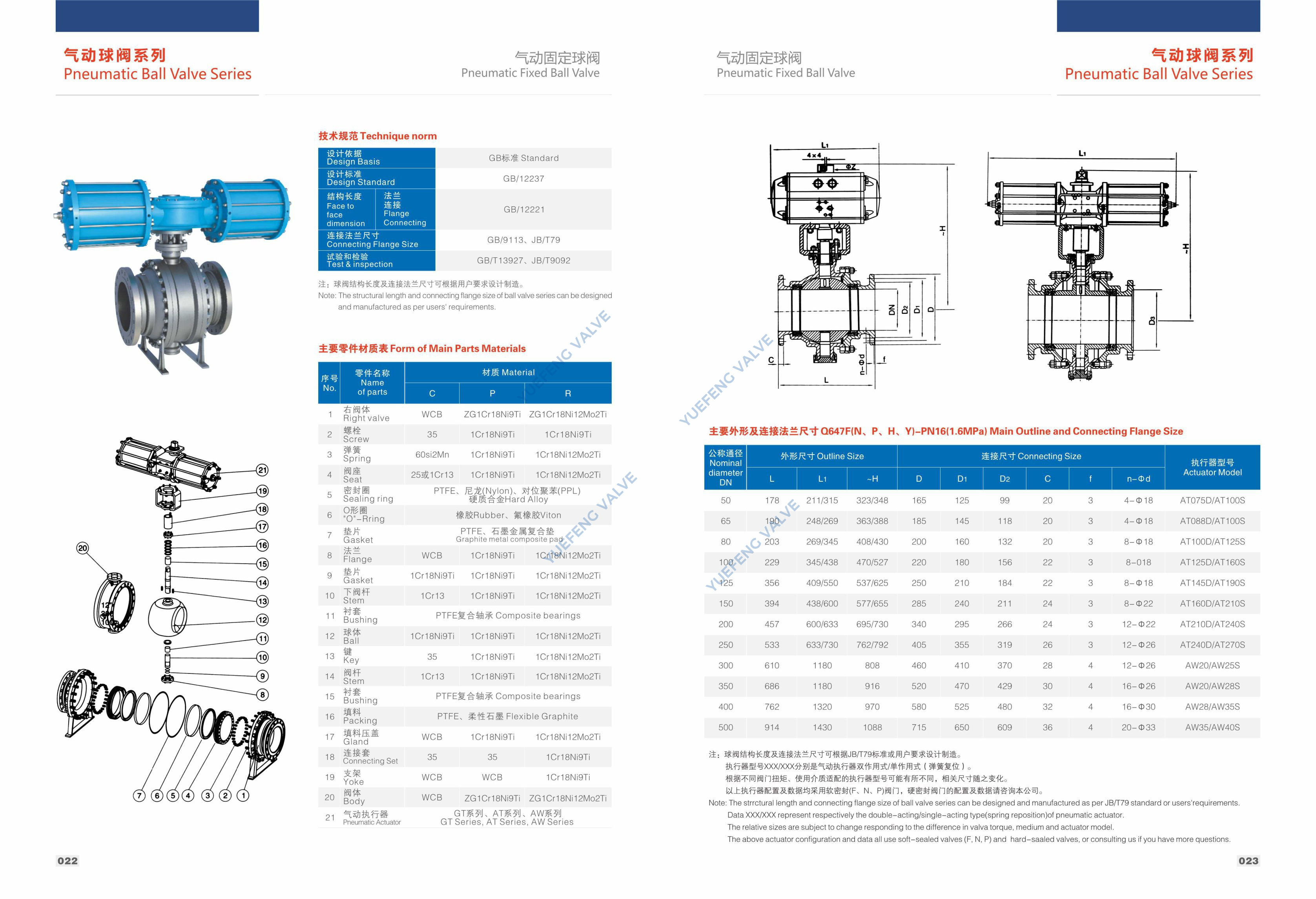

Key components are crafted from top-grade materials to enhance performance and corrosion resistance. Valve bodies and flanges use WC8, 1Cr18Ni9Ti, or ZG1Cr18Ni12Mo2Ti, while stems and balls adopt 1Cr13 or 1Cr18Ni9Ti for strength. Sealing Materials include PTFE, Nylon, PPL (for soft seals) and hard alloy (for hard seals), providing excellent resistance to chemicals, abrasion, and extreme temperatures.

The valve’s sealing system is engineered for zero or minimal leakage. Soft-sealed versions (F, N, P) are ideal for low-to-medium pressure and non-corrosive media, while hard-sealed options excel in high-pressure, high-temperature, or abrasive environments. The combination of precision-machined balls and seats ensures tight sealing, meeting GB/T13927 and JB/T9092 test standards.

Paired with AT/AW/GT Series Pneumatic Actuators, the valve offers rapid response times and precise flow control. Double-acting actuators (designated with "D") require air supply for both opening and closing, while single-acting (spring return, designated with "S") ensures fail-safe operation during power or air loss. Actuator torque is perfectly matched to valve size, from AT075D for DN50 to AW40S for DN500, ensuring smooth and reliable actuation.

To meet unique application needs, the valve supports customization of structural length and flange size per user requirements or JB/T79 standards. Whether adapting to special installation spaces or specific media conditions, our engineering team tailors configurations to optimize performance and compatibility.

Ideal for crude oil, natural gas, and refined product transmission systems. The valve’s corrosion-resistant materials and high-pressure rating (up to PN40) withstand harsh downhole and pipeline conditions, ensuring leak-proof operation in upstream, midstream, and downstream processes.

Suitable for handling corrosive chemicals, acids, alkalis, and solvents. Soft-sealed versions with PTFE or PPL seals prevent media contamination, while hard-sealed options endure high temperatures and pressure fluctuations in reactor outlets, distillation columns, and chemical transfer lines.

Used in potable water supply, wastewater treatment, and irrigation systems. The valve’s smooth flow path minimizes clogging, and food-grade sealing materials comply with hygiene standards. Flange connection ensures secure integration with water pipelines, supporting flow regulation and system isolation.

Critical for boiler feedwater, steam control, and cooling water systems in thermal and nuclear power plants. The valve’s high-temperature resistance (via premium alloys) and reliable sealing handle steam pressure up to PN40, ensuring efficient energy production and system safety.

Adopted in fluid transfer lines for beverages, dairy products, and processed foods. Soft-sealed configurations with food-grade Nylon or PTFE seals prevent contamination, meeting strict industry hygiene requirements.

Our valves cover three primary Pressure Ratings: PN16 (1.6MPa), PN25 (2.5MPa), and PN40 (4.0MPa). These ratings are engineered to meet the demands of low, medium, and high-pressure industrial systems, with test standards compliant with GB/T13927 and JB/T9092 for leak-tight performance.

The valve is available in Nominal Diameters (DN) from DN50 to DN500, covering most industrial pipeline sizes. Each size is paired with a matched pneumatic actuator (e.g., AT075D for DN50, AW40S for DN500) to ensure optimal torque and actuation efficiency.

Soft-sealed Valves (F, N, P) are recommended for non-corrosive media, normal temperatures (≤180℃), and low-to-medium pressure (PN16-PN25), offering excellent sealing tightness. Hard-sealed Valves are ideal for high temperatures (≤425℃), high pressure (PN40), or abrasive/corrosive media, providing enhanced durability and wear resistance. Contact our team for media-specific recommendations.

Compliant with rigorous standards including GB/12237 (design), GB/12221 (structural length), and GB/9113/JB/T79 (flange connection), this valve ensures compatibility and reliability in global industrial systems. It features a Flange Connection design for secure installation, covering a wide range of Nominal Diameter (DN) from DN50 to DN500 and Pressure Rating (PN) of PN16 (1.6MPa), PN25 (2.5MPa), and PN40 (4.0MPa) to meet diverse pressure requirements. Equipped with high-efficiency Pneumatic Actuators (AT, AW, and GT series), the valve supports both double-acting and single-acting (spring return) operation, delivering fast response and stable torque output. Available in Soft-sealed Valves (F, N, P) and Hard-sealed Valves configurations, it adapts to varying media characteristics, from non-corrosive fluids to high-temperature, high-pressure harsh conditions.

Built on GB/12237 and GB/12221 standards, the valve’s structural length and flange dimensions are optimized for durability and interchangeability. The fixed ball design minimizes fluid turbulence, reducing wear on internal components and ensuring long-term operational stability. Flange connections adhere to GB/9113 and JB/T79 specifications, guaranteeing leak-proof assembly and resistance to high pressure.

Key components are crafted from top-grade materials to enhance performance and corrosion resistance. Valve bodies and flanges use WC8, 1Cr18Ni9Ti, or ZG1Cr18Ni12Mo2Ti, while stems and balls adopt 1Cr13 or 1Cr18Ni9Ti for strength. Sealing Materials include PTFE, Nylon, PPL (for soft seals) and hard alloy (for hard seals), providing excellent resistance to chemicals, abrasion, and extreme temperatures.

The valve’s sealing system is engineered for zero or minimal leakage. Soft-sealed versions (F, N, P) are ideal for low-to-medium pressure and non-corrosive media, while hard-sealed options excel in high-pressure, high-temperature, or abrasive environments. The combination of precision-machined balls and seats ensures tight sealing, meeting GB/T13927 and JB/T9092 test standards.

Paired with AT/AW/GT Series Pneumatic Actuators, the valve offers rapid response times and precise flow control. Double-acting actuators (designated with "D") require air supply for both opening and closing, while single-acting (spring return, designated with "S") ensures fail-safe operation during power or air loss. Actuator torque is perfectly matched to valve size, from AT075D for DN50 to AW40S for DN500, ensuring smooth and reliable actuation.

To meet unique application needs, the valve supports customization of structural length and flange size per user requirements or JB/T79 standards. Whether adapting to special installation spaces or specific media conditions, our engineering team tailors configurations to optimize performance and compatibility.

Ideal for crude oil, natural gas, and refined product transmission systems. The valve’s corrosion-resistant materials and high-pressure rating (up to PN40) withstand harsh downhole and pipeline conditions, ensuring leak-proof operation in upstream, midstream, and downstream processes.

Suitable for handling corrosive chemicals, acids, alkalis, and solvents. Soft-sealed versions with PTFE or PPL seals prevent media contamination, while hard-sealed options endure high temperatures and pressure fluctuations in reactor outlets, distillation columns, and chemical transfer lines.

Used in potable water supply, wastewater treatment, and irrigation systems. The valve’s smooth flow path minimizes clogging, and food-grade sealing materials comply with hygiene standards. Flange connection ensures secure integration with water pipelines, supporting flow regulation and system isolation.

Critical for boiler feedwater, steam control, and cooling water systems in thermal and nuclear power plants. The valve’s high-temperature resistance (via premium alloys) and reliable sealing handle steam pressure up to PN40, ensuring efficient energy production and system safety.

Adopted in fluid transfer lines for beverages, dairy products, and processed foods. Soft-sealed configurations with food-grade Nylon or PTFE seals prevent contamination, meeting strict industry hygiene requirements.

Our valves cover three primary Pressure Ratings: PN16 (1.6MPa), PN25 (2.5MPa), and PN40 (4.0MPa). These ratings are engineered to meet the demands of low, medium, and high-pressure industrial systems, with test standards compliant with GB/T13927 and JB/T9092 for leak-tight performance.

The valve is available in Nominal Diameters (DN) from DN50 to DN500, covering most industrial pipeline sizes. Each size is paired with a matched pneumatic actuator (e.g., AT075D for DN50, AW40S for DN500) to ensure optimal torque and actuation efficiency.

Soft-sealed Valves (F, N, P) are recommended for non-corrosive media, normal temperatures (≤180℃), and low-to-medium pressure (PN16-PN25), offering excellent sealing tightness. Hard-sealed Valves are ideal for high temperatures (≤425℃), high pressure (PN40), or abrasive/corrosive media, providing enhanced durability and wear resistance. Contact our team for media-specific recommendations.